Post combustion capture of carbon dioxide

What is post-combustion capture?

The effective capture of carbon dioxide (CO2) emitted from industrial processes is an important strategy in the reduction of greenhouse gas emissions in NSW.

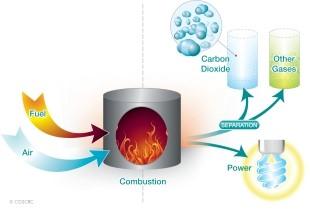

One of the most promising capture methods available is post-combustion capture (PCC) which involves the separation and concentration of the CO2 from flue gas obtained after the combustion of coal.

This technology has desirable advantages. It is based on mature techniques currently used in oil refineries, petrochemical plants and other industries, and it can be retrofitted to existing processes. This negates the expensive task of constructing or substantially modifying existing facilities and hence provides an avenue for near-term CO2 capture.

The Post-combustion capture process. Courtesy of CO2CRC.

Various techniques are being developed throughout the world to effectively capture CO2 in a cost-efficient manner. The leading technology is based on liquid absorbent capture technology which uses chemical liquids to specifically target and remove the CO2 from the flue gas stream. Other technologies, such as membrane sieves and physical adsorption, are also being investigated as alternative or supplementary options to chemical liquid absorption.

Twelve projects have been supported by the Coal innovation NSW Fund to assist improved capture and abatement of greenhouse gas emissions.

Project: Further development of an aqueous ammonia process for post-combustion capture of CO2 in the NSW power sector

The challenge:

To evaluate and assess solvent based post combustion capture technologies at a pilot scale with real flue gas conditions in NSW coal fired power stations

The action:

Coal Innovation NSW funded CSIRO to develop a post combustion capture pilot plant test facility for NSW coal fired power stations.

Grant amount:

$1.3 million (EOI Round 2009)

The project:

CSIRO Energy Technology received grant funding in 2010 to support a research and development program dedicated to the chemical capture of CO2 emitted in the flue gas from NSW coal-fired power stations. This project was designed to enable further development of PCC in preparation for a larger scale demonstration of the technology.

This successful project involved the refurbishment and modification of a post combustion pilot plant following its transportation from Munmorah Power Station to Vales Point Power Station. This pilot plant is now a critical piece of test infrastructure that can stage many different experimental campaigns on real flue gas under real power station operating conditions.

So far three projects have been completed with the support of the pilot plant including the:

- CSIRO’s ‘Site Trials of Novel CO2 Capture Technology at Delta Electricity ’ Project - funded by Coal Innovation NSW

- University of New South Wales’ ‘Evaluation of CO2 Capture with High Performance Hollow Fiber Membranes from Flue Gas: A Pilot Scale Study’ Project – funded by ANLEC R&D/CO2CRC

- CSIRO’s ‘Hybridisation of concentrated solar thermal with carbon capture and storage’ Project – funded by Australian Renewable Energy Association (ARENA)

This project has been completed and the final report, Delta Electricity PCC pilot plant relocation from Munmorah to Vales Point Power Station – Technical Report (PDF, 7.2 MB), contains further details of its findings.

Project: Site trials of novel CO2 capture technology at Delta Electricity

The challenge:

Finding new ways to make the post-combustion capture of CO2 more commercially viable.

The action:

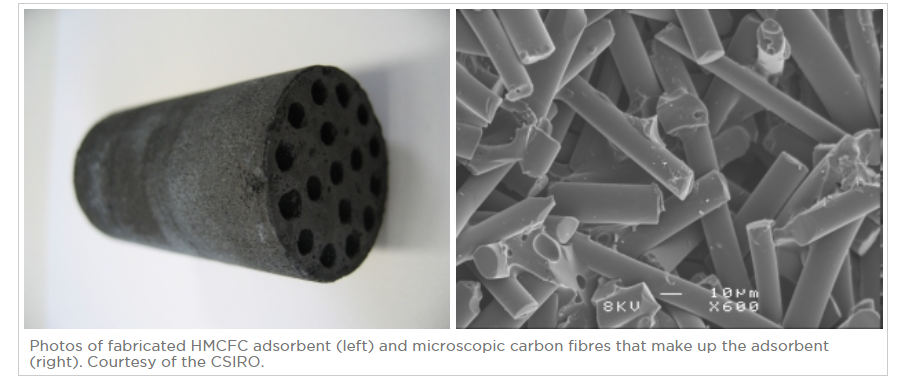

Coal Innovation NSW funded CSIRO Coal Technology to investigate a novel technology to physically separate CO2 from flue gas.

Grant amount:

$616,711 (EOI Round 2009)

The project:

CSIRO Coal Technology received grant funding in 2010 to investigate the ability of a novel, patented technology to physically separate CO2 from the flue gas emitted from NSW coal-fired power stations.

It uses a type of nano-structured Monolithic Carbon Fibre Composite adsorbent material fabricated in a Honeycomb structure (HMCFC absorbent). The promoted benefit of this technology is that it enables dry CO2 capture at room temperature and atmospheric pressure, and in dusty environments with low pressure drop, thereby reducing the operational and maintenance cost of the post-combustion capture process.

The site trials were a world first in demonstrating such solid sorbents on real flue gas. The important experimental data and site operational experience obtained at the power station form a good basis for further development of the technology. The resulting report, Site Trials of Novel CO2 Capture Technology at Delta Electricity (PDF, 5.85 MB), contains further details of the project findings.

Project: Advanced aqueous ammonia-based carbon capture technology

The challenge:

Proving the feasibility of new solvent-based post-combustion capture technologies for NSW coal-fired power stations.

The action:

Coal Innovation NSW funded CSIRO Energy to further develop and demonstrate the use of ammonia for CO2 capture.

Grant amount:

Up to $2 million (EOI Round 2015)

The project:

This technology uses a cheap, stable and locally available chemical, ammonia, as the absorption solvent to remove CO2, SO2 and other pollutants from the flue gas of power stations and other industries.

The project aims to demonstrate an advanced aqueous ammonia-based post-combustion CO2 capture process, developed by CSIRO, and its benefits, through the use of the pilot plant located at Vales Point Power Station.

An additional laboratory stream focuses on the proof of concept and prototyping of an entirely new process to take advantage of the volatility of ammonia to capture CO2, called the “Trimonia Process”.

This project has been completed and the final report, Pilot-plant and laboratory demonstration of advanced aqueous ammonia-based CO2 capture technologies, contains further details of the project findings.

Photo of the PCC pilot plant at Vales Point power station, courtesy of Hai Yu, CSIRO

Project: Rotating liquid sheet contactor pilot scale testing

The challenge:

Improving the effectiveness of post combustion capture processes under real flue gas conditions in NSW.

The action:

Coal Innovation NSW funded CSIRO Energy to design and test a Rotating Liquid Sheet (RLS) contactor for better dispersion and CO2 capture.

Grant amount:

Up to $1.27 million (EOI Round 2015).

The project:

The RLS contractor is a potentially more efficient type of gas separation technology that uses a rotating device to spray out a continuous thin liquid sheet that would contact and absorb the CO2 emitted in the flue gas from a coal-fired power station.

The aim of the project is to validate the design, costs and performance of the RLS contactor in a post-combustion CO2 capture cycle, using real flue gas in the pilot plant at the Vales Point Power Station.

If proven, this novel technology could be incorporated into a conventional CCS process and be retrofitted to existing coal-fired power stations to reduce their carbon emissions by more than 90%.

The RLS contactor can be considered a ‘platform’ technology, which could be applied to several applications and industries. These ‘spin-off’ applications may even pay for its commercialisation prior to its application to the post combustion capture of CO2.

The project has been completed and the final report, Rotating Liquid Sheet contactor, contains further details of the project findings.

Laboratory scale Rotating Liquid Sheet contactor (photo courtesy of Leigh Wardhaugh, CSIRO Energy)

Project: Membrane gas-solvent contactor demonstration

The challenge:

Identifying new technologies to improve the cost-effectiveness of post combustion capture processes to make Carbon Capture and Storage (CCS) more economically viable.

The action:

Coal Innovation NSW funded CO2CRC to develop and trial Membrane Gas-Solvent contactors at a pilot scale to capture CO2.

Grant amount:

Up to $1.21 million (EOI Round 2015).

The project:

CO2CRC is receiving funding to develop and pilot trial Membrane Gas-Solvent contactors, which are a combination of gas separation technologies, for the capture of CO2 from flue gas in a pilot plant at the Vales Point Power Station.

The project will establish the viability of this new hybrid technology and provide the necessary data to enable design scaling to support a potential large-scale CO2 capture demonstration.

The aim of the project is to commission a membrane contactor pilot plant, the largest of its kind in the world, at the Vales Point Power Station to capture 100,000 kg of CO2 per day with up to 20-30% reduction in capital cost when compared to current solvent-based CO2 capture systems.

If this can be achieved at scale, it would enable this technology to be cost-competitive and help drive down the costs of capturing CO2 for Carbon Capture and Storage (CCS).

The project has been completed and the final report, Membrane Gas-Solvent Contactor Pilot Plant Trials at Vales Point Power Station, contains further details of the project findings.

Pilot membrane gas solvent contactor in development (photo courtesy of Abdul Qader, CO2CRC)

Project: Third generation membrane material development

The challenge:

Identifying new technologies to improve the cost-effectiveness of post-combustion capture processes to make Carbon Capture and Storage (CCS) more economically viable.

The action:

Coal Innovation NSW is funding the University of NSW to develop a new generation of membrane material to capture CO2 and test it under real flue gas conditions.

Grant amount:

Up to $862,803 (EOI Round 2015)

The project:

The University of New South Wales is receiving funds to develop a new generation membrane material and test it under real flue gas conditions at Vales Point Power Station.

Membrane technology is a physical separation process like sieving, a technology currently used in the gas industry for separating gas mixtures into constituent gases. A unique feature of this project is that all the materials used for membrane development are commercially available and therefore the process developed in this study is suited to existing large-scale fabrication used in membrane production.

This project has the potential to provide a pathway for translating membrane technology for carbon capture into industrial scale manufacturing in NSW.

The project has been completed and the final report contains further details of the project findings.

Commercial PVDF hollow fibre membranes used as support layer for new generation membrane (photo courtesy of Vicki Chen, University of New South Wales)

Project: Aerosol formation pathways in liquid absorption-based CO2 capture process

Case study of an MEA-based PCC plant at Vales Point power station

The challenge:

To better understand aerosol formation from liquid absorption-based CO2 capture plants to reduced costs and meet regulatory requirements in coal-fired power plant operation.

The action:

Coal Innovation NSW funded CSIRO to investigate aerosol formation from solvents used in the post-combustion capture (PCC) process through laboratory and pilot-plant based research.

Grant value:

Up to $687,252 (EOI Round 2015)

The project:

This project evaluated the potential for aerosol production from PCC process at coal-fired power stations.

A literature review was conducted that specifically focused on aerosol formation from SO2, SO3 and NOX, the target gases that the grantee explored in their experimental campaign. The main findings of this review were:

- There is international scientific consensus that aerosol released from stack emissions of PCC plants will be a significant problem for the deployment of PCC technology; and

- The oxides of sulphur, specifically SO3, have shown to be strong drivers for aerosol formation.

The grantee’s experimental campaign confirmed that sulphur oxides have a strong propensity to form aerosols. This study reinforces the importance of maintaining low SOX and NOX in flue gas to minimise aerosol genesis in the PCC processes.

The project has been completed and the final report, Aerosol-formation pathways in a liquid absorption-based CO2-capture process (PDF, 3.43 MB), contains further details of the project findings.

Post combustion Capture Solvent Degradation Rig used for the aerosol formation case study (Courtesy of Brendan Halliburton, CSIRO)

Project: Retrofitting calcium carbonate looping to an existing cement plant for CO2 capture: A techno-economic feasibility study

The challenge:

Identifying new ways to cost-effectively reduce CO2 emissions from the manufacture of cement.

The action:

Coal Innovation NSW funded the CSIRO to undertake a techno-economic evaluation of a novel technology for capturing the CO2 released from cement production using Boral’s Berrima cement plant as a model.

Grant amount:

$100,000 (EOI Round 2018)

The project:

The project aimed to investigate the feasibility of retrofitting the Boral’s Berrima cement plant, a major emitter of CO2, with a novel PCC process based on calcium carbonate looping (CCL) to reduce CO2 emissions. The CCL process exploits the reaction between lime and CO2 to form limestone, which can then be reversed to release a high purity stream of CO2 ready for geological storage. The technology shares inherent synergies with the cement industry as limestone is an input to the cement-making process.

A new CCL process was proposed and evaluated for its suitability for retrofitting to the cement plant, which through the inclusion of a specially designed reactor, eliminated the need for some of the expensive equipment required in a conventional CCL system. Overall, the novel process was found to reduce carbon emissions from the existing cement plant by more than 80% and was more cost-competitive than other PCC technologies suitable for deployment in the cement industry.

Project: Water production from CO2 capture

The challenge

Make post-combustion capture of CO2 more commercially viable by reducing the water requirement.

The action

Coal Innovation NSW funded the CSIRO to address the problem of increased power station water requirements as a result of CO2 post combustion capture through a pilot-scale demonstration of water production from a modified amine-based CO2 capture process.

Grant amount

$1.34 million (EOI Round 2018).

The project

This project undertook a pilot plant demonstration of a desalination process integrated with an amine-based CO2-capture process. This addresses the obstacle of increasing specific cooling load and hence increased water requirement of coal-fired power plants, as a result of the implementation of CO2 capture. In this project, the grantee investigated various combinations of absorption liquids and forward osmosis (FO) and vacuum distillation membranes in the laboratory, before progressing to trials at Delta Electricity’s Vales Point Power Station.

The project goals included establishing principles underpinning the process and equipment design, identification of the most suitable or best-performing desalination membrane for incorporation into amine carbon capture, and a techno-economic evaluation of the process concept for NSW coal-fired power plants.

The project was successful in progressing both technological innovations. Through pilot-plant experiments at Vales Point Power Station, amino-acid salts were found to be the best preforming absorption liquid for the forward osmosis process. These solutions were also identified through lab trials to be best suited for membrane distillation, but were not trialled at the pilot scale due to a lack of reliable commercially available membranes.

The techno-economic assessment highlighted both the need to continue to develop the technology, and its application in water constrained areas in Australia.

The project has been finalised and the final report has been approved by the CINSW board, which contains further details of the project findings.

Project: Harnessing energy with CO2 utilisation - a feasibility study

The challenge:

Improve the economic performance of technologies that capture and utilise CO2.

The action:

Coal Innovation NSW funded the CSIRO to assess the feasibility of a novel electrochemical technology that harvests electrical energy and produces a saleable product (bicarbonate soda) by mixing CO2 that has been absorbed into a liquid solvent as part of a post-combustion capture (PCC) process, with wastewater brine rejects from coal mines.

Grant amount:

$154,923 (EOI Round 2018).

The project:

This project involves a feasibility study of a novel method of simultaneously mixing CO2, that has been absorbed into a liquid CO2 capture solvent as part of a PCC process, with wastewater brine rejects from coal mines in order to harvest electrical energy and produce a saleable product (bicarbonate soda).

The fundamental principle behind this technology is harnessing the mixing energy of two aqueous electrolytes through porous carbon composite electrodes, as well as using the CO2 mineralisation process to produce a useful carbonate salt. The ability to strip out the CO2 from the capture solvent (i.e. regenerate the solvent back to its original state) used in a PCC process also offers a potentially more efficient alternative to conventional thermal regeneration techniques. CSIRO has developed electrodes made from carbon composites considered suitable for this process.

Following the development of process configurations and mass balances, preliminary LCA and economic evaluation were carried out to assess the feasibility of the electrochemical processes. The key performance indices for the economic evaluation were the leveled cost of electricity and CO2 avoided cost for each electrochemical cell integrated with a power station with amine-based PCC. It showed that the PZ/AMP-based CO2 utilisation reaction cell process was the most economically favourable. The grantee notes the path to commercialisation as being the validation of the technology at a laboratory scale followed by a demonstration plant. They also note the barriers as being the availability of inputs from industrial processes required to make the process commercially viable.

The project has been completed and the final report, Harnessing energy with CO2 utilisation – a feasibility study (PDF, 1.21 MB), contains further details of the project findings.

Project: A novel platform for highly integrated solar heat in carbon capture technology

The challenge:

Identifying new methods to improve the efficiency of CO2 post-combustion capture processes.

The action:

Coal Innovation NSW funded the CSIRO to study a new method of directly applying solar thermal energy to regenerate PCC chemical absorbents as a means of reducing the parasitic energy demand placed on the power station by the stripping process.

Grant amount:

$505,145 (EOI Round 2018).

The project:

This project involved a desktop investigation of the use of a customised solar-stripper array as an alternative means of removing carbon dioxide in the carbon capture process. One of the most effective methods to reduce carbon dioxide emissions, particularly from the use of fossil fuels, is amine-based post combustion capture (PCC). PCC processes, however, have a significant thermal energy demand resulting in an overall reduction in net power production. The proposed innovation entails the direct use of solar heat for solvent regeneration, eliminating the desorber unit from the PCC process. This offers the prospect of reducing PCC capital and operating costs, and the efficient utilisation of a small solar field to reduce the energy penalty of the carbon capture process. This innovative approach also allows the capture process to be independent from the power cycle. The project is complete and the final report: A novel platform for highly integrated solar heat in carbon capture technology, contains further details of the project findings (PDF, 7.3 MB).

Project: Reduction of greenhouse gas emissions in steel production

The challenge:

Identifying ways to cost-effectively reduce CO2 emissions from the manufacture of steel.

The action:

CINSW funded the CO2CRC to assess the pathways for reducing CO2 emissions in the steel-making process through carbon capture and storage and the use of innovative CO2 utilisation technologies.

Grant amount:

$387,550 (EOI Round 2018).

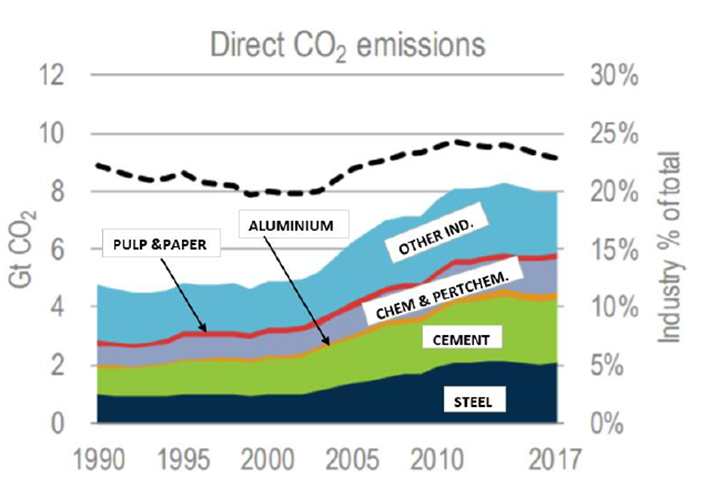

The project:

Total decarbonisation of the steel industry is not currently feasible due to the inherent use of coal and coke in the steel making process. This project included a global literature review of current and emerging emissions reduction technologies and energy efficiency schemes used in steel manufacture. The study included an analysis of the technologies available for steel plants to implement these schemes.

This study proposed three pathways to reduce CO2 emission at BlueScope’s Port Kembla Steelworks based on the three major options; energy efficiency, CCUS and CCS. A biochemical process developed by Lanzatech that produces ethanol via bio-fermentation of carbon-rich steel mill gases was reviewed. The technology was shown to be a commercially viable means of reducing the carbon content of these gases by 10-15%.

Energy efficiency measures were reviewed and noted as a pathway to emissions reduction. Many of the measures were already implemented at Port Kembla and many of these efficiency measures are close to their thermodynamic energy thresholds. This means the scope for improvement is limited particularly when retrofitting to steel plants.

Post combustion capture (PCC) of CO2 was the most effective way to achieve large scale emissions reduction at Port Kembla. PCC could reduce emissions by 2.86 million tonnes per annum, or 45% of total emissions from the steelworks.

The project has been completed and the final report, Reduction of Greenhouse Gas Emissions in Steel Production (PDF, 3.97 MB), contains further details of the project findings.

Global industrial direct CO2 emissions (Image courtesy of CO2CRC)

At times, we publish documents and publications received from third parties. These third party documents may not adhere to the standards followed by the Department of Primary Industries and Regional Development.